Three major pain points in the battery cell industry:

- Destructive testing: Traditional sampling inspection requires cutting samples, causing waste;

- Delayed results: Inspection reports take several hours to wait for;

- High Misjudgment Rate: A 30% error rate poses potential safety hazards.

Revolutionary solution

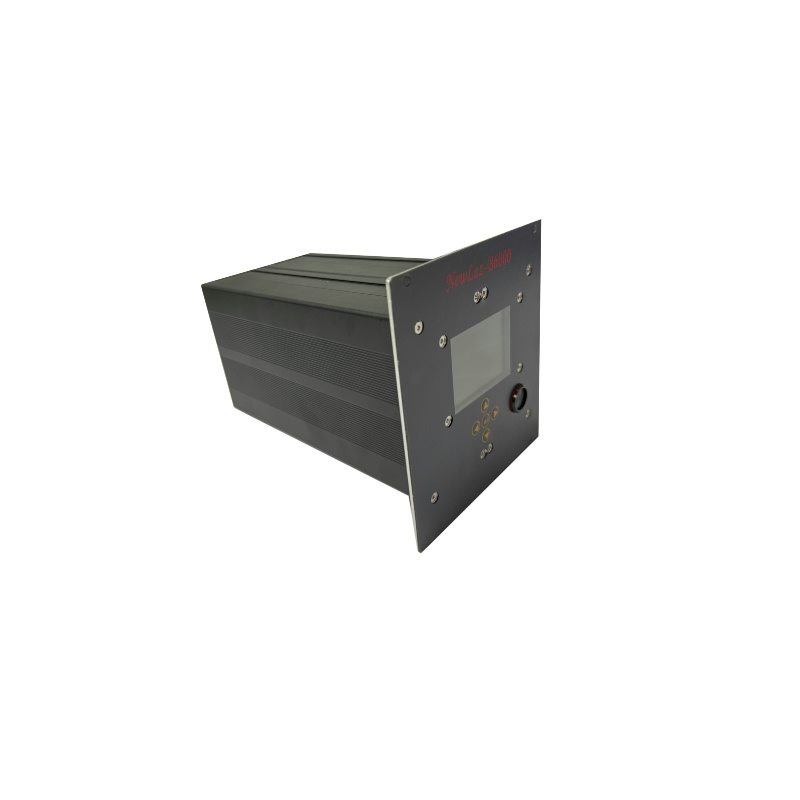

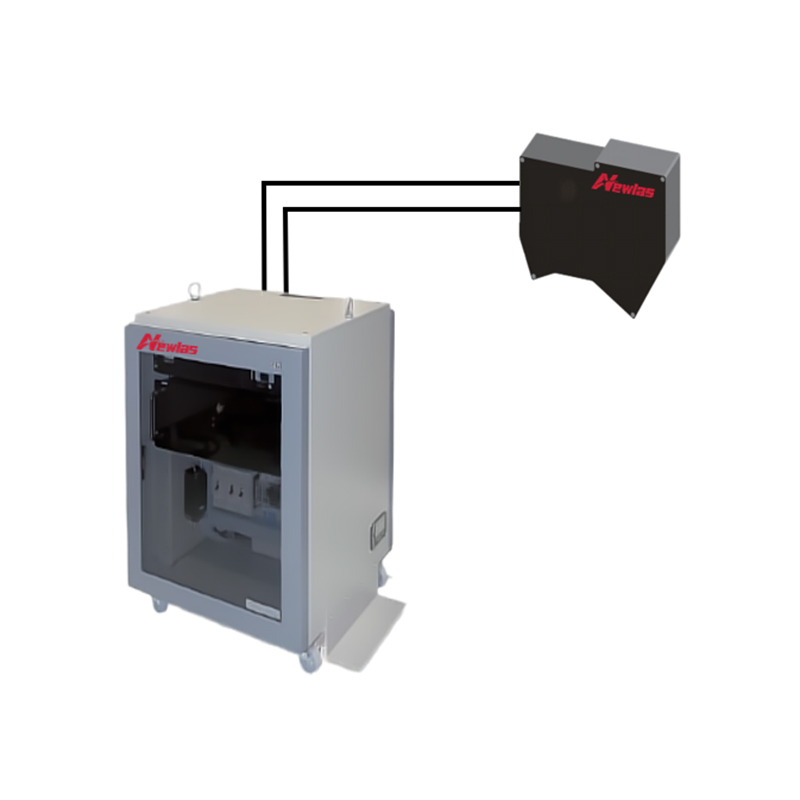

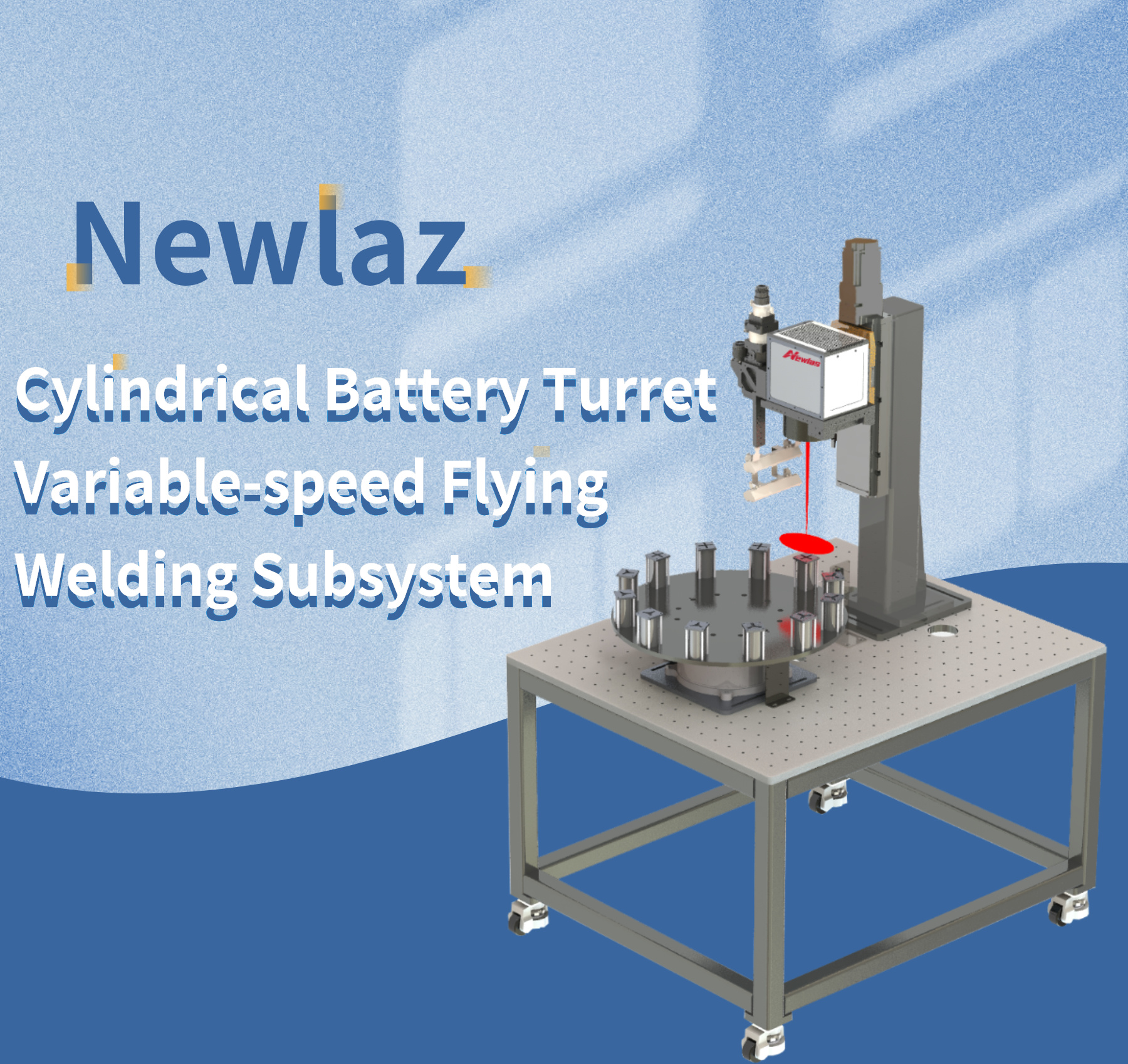

Three Breakthroughs of the Newlas NewOCT Detection System:

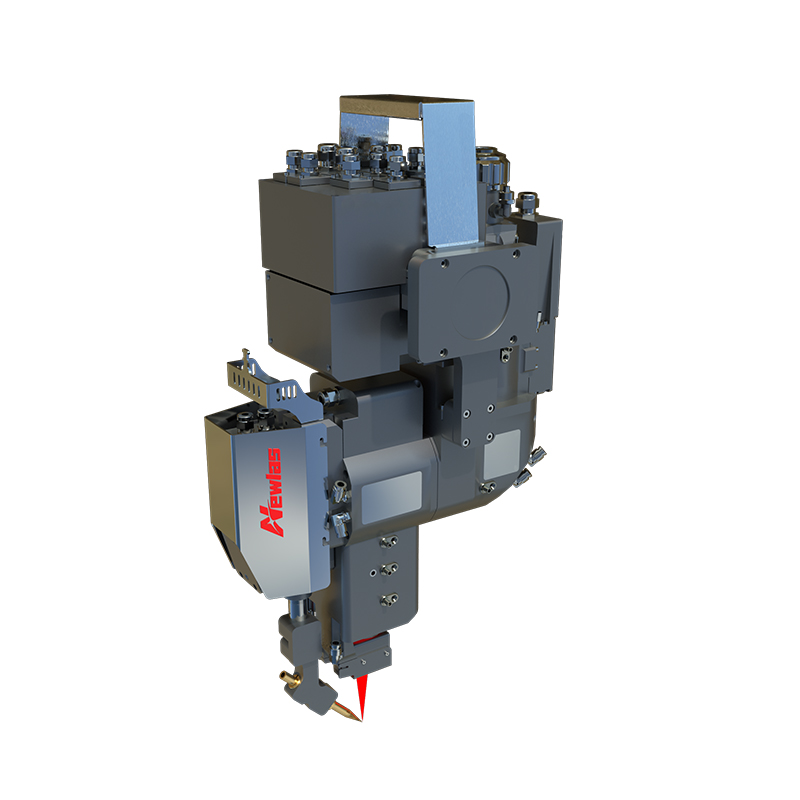

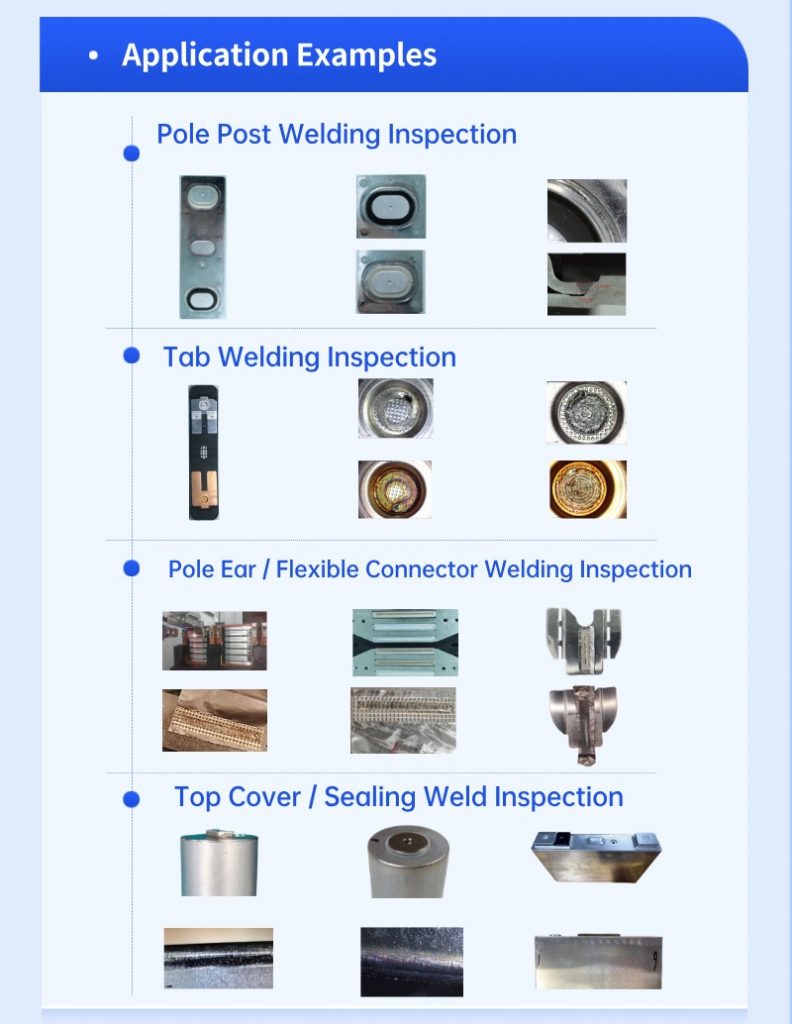

Non-destructive Full Inspection: Optical scanning technology with micrometer-level precision;

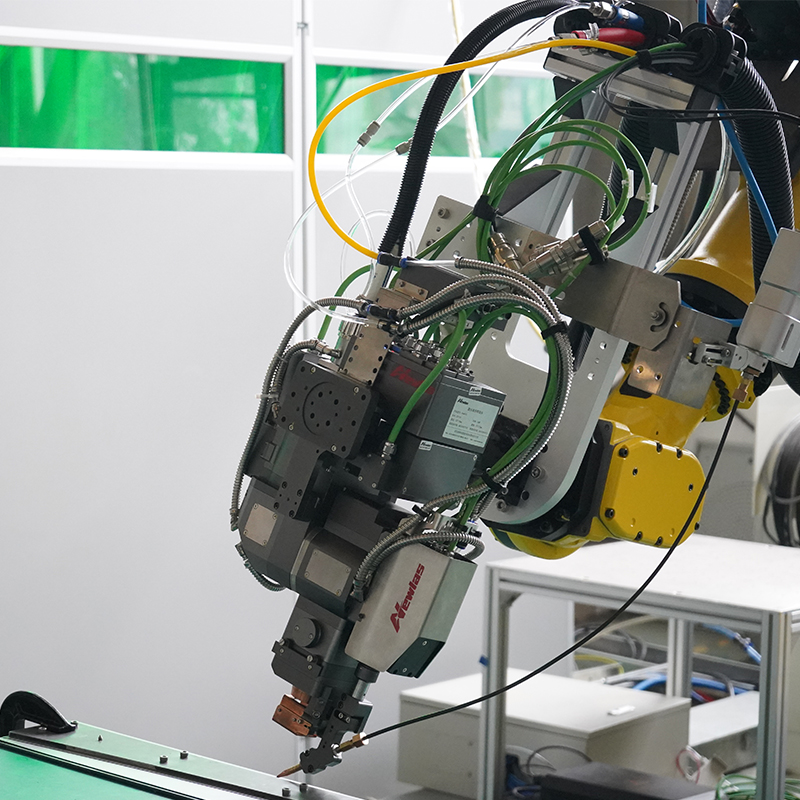

Real-time Regulation: Millisecond-level data feedback for automatic parameter optimization;

Zero Missed Inspection: 100% full inspection, making false welding impossible to hide.

Core Advantages

- Backed by 12 Patented Technologies: Including optical path compensation, dual-control system, etc.;

- Intelligent Early Warning System: Detects equipment abnormalities in advance to reduce downtime;

- Full Process Compatibility: Compatible with prismatic, cylindrical and pouch batteries.

Visible Benefits

- Cost Savings: Reduces manual inspection costs;

- Quality Assurance: Inspection error ≤ 10%, eliminating batch defects;

- Efficiency Improvement: Real-time inspection for smoother production processes.