Exhibition Express

The 17th Shenzhen International Battery Technology Exchange Conference/Exhibition

Time: May 15-17, 2025

locations: Shenzhen International Convention and Exhibition Center

Newlas Booth: 9T118

Sneak peek at the most important exhibits

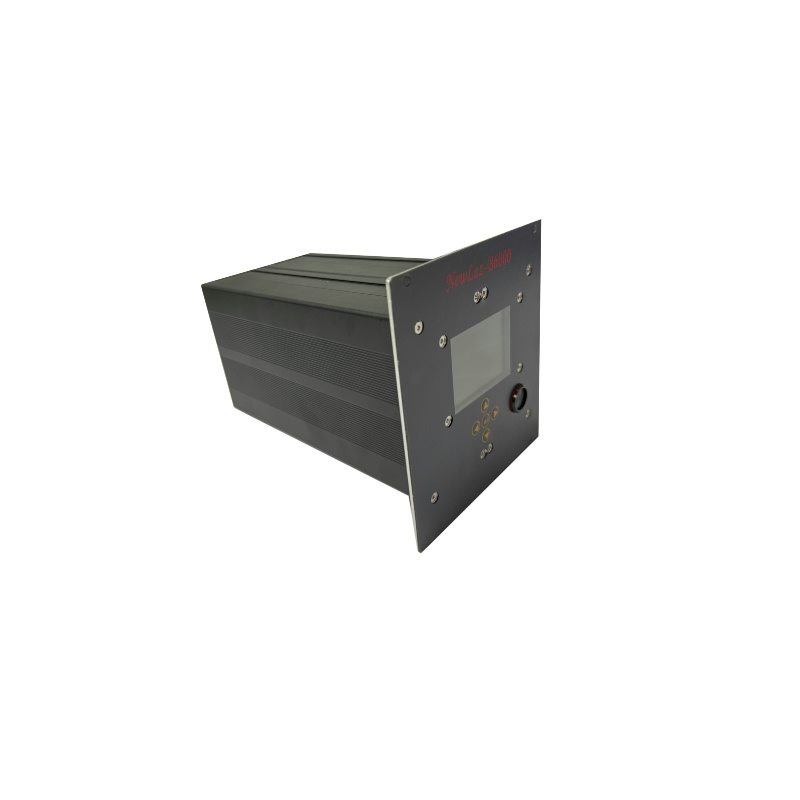

01 NewOCT Laser Welding Penetration Detection System

- Technological breakthrough: galvanometer + OCT technology integration, 10μm-level three-dimensional imaging, no missed detection;

- Core value: welding inspection is completed simultaneously, efficiency is improved by 30%, batch application of leading enterprises, and zero-defect control of production lines;

- Industry benchmark: OctMetrix intelligent engine, plug-and-play, full-scenario adaptation.

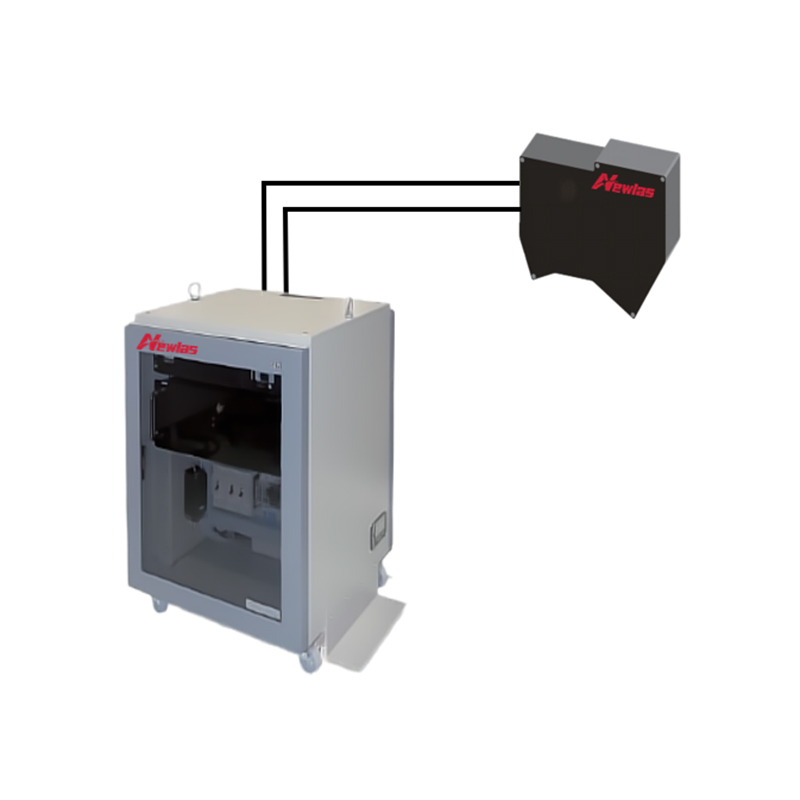

02 NewScan high power laser flying welding system

- Efficiency revolution: millisecond-level positioning, production efficiency increased by 20%-50%;

- Intelligent process: spiral spot welding + sensor anti-fool technology, welding yield 99.9%;

- Scenario coverage: adapt to power battery poles, Busbar full-scenario high-speed welding.

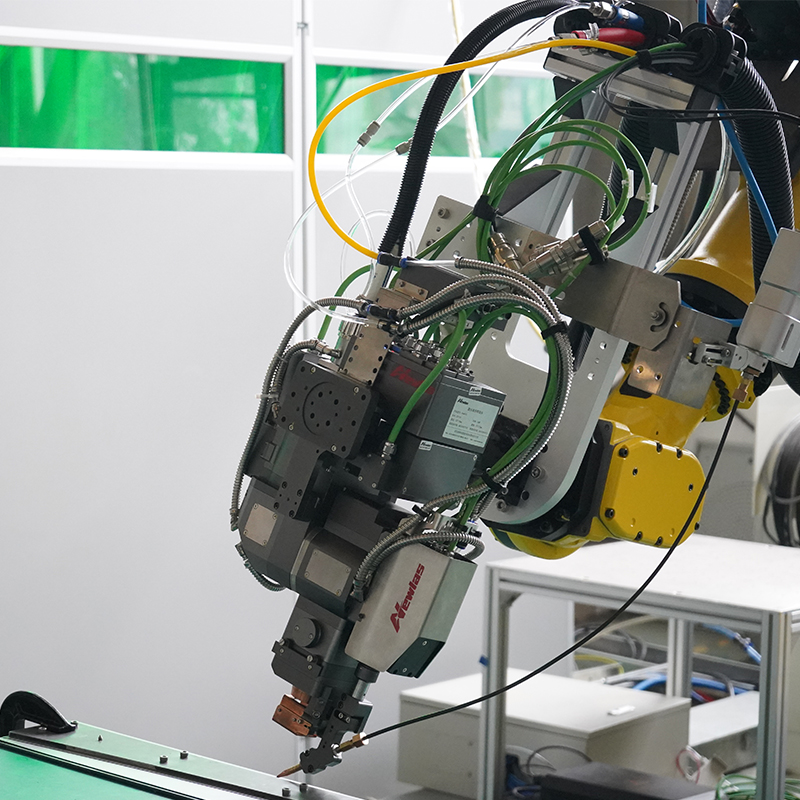

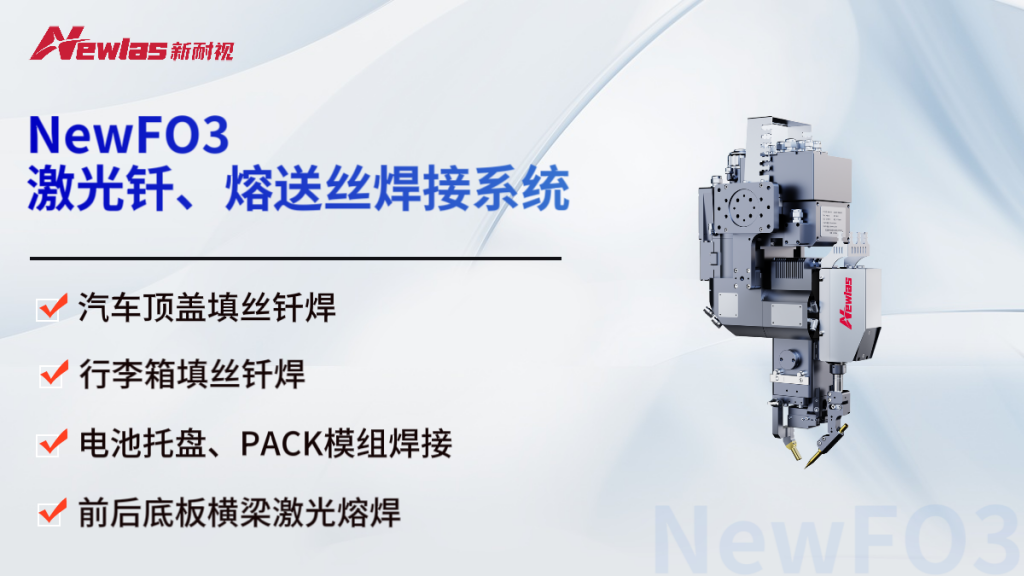

03 NewFO3 wire feeding brazing welding system

- Domestic first: high-precision weld tracking, automatic compensation of welding spot size;

- Expert in complex scenes: long straight line/curve welding without pressure, compatible with multiple types of laser light sources, beautiful and reliable welds.

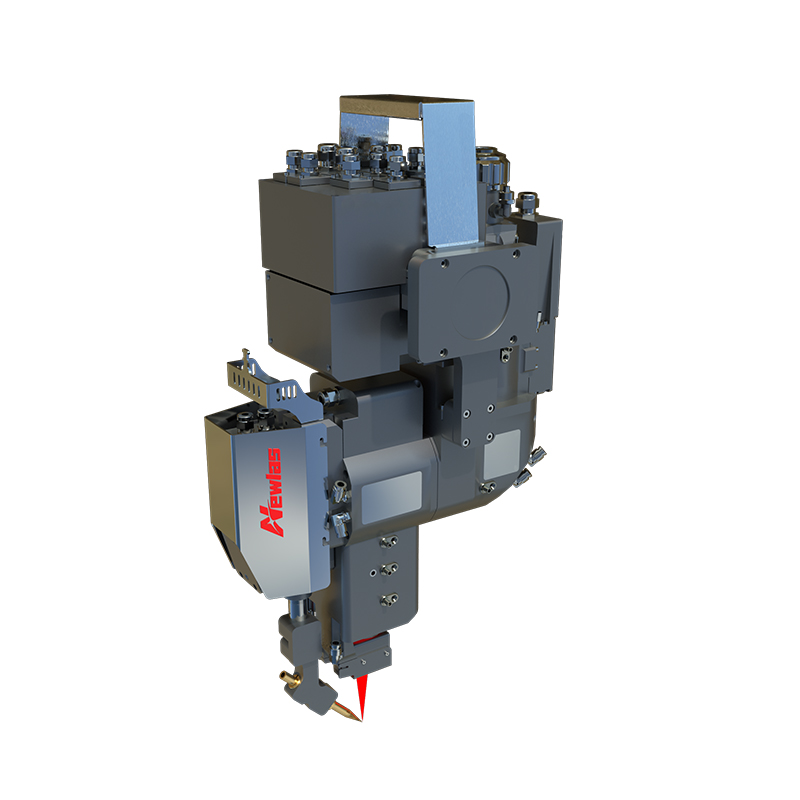

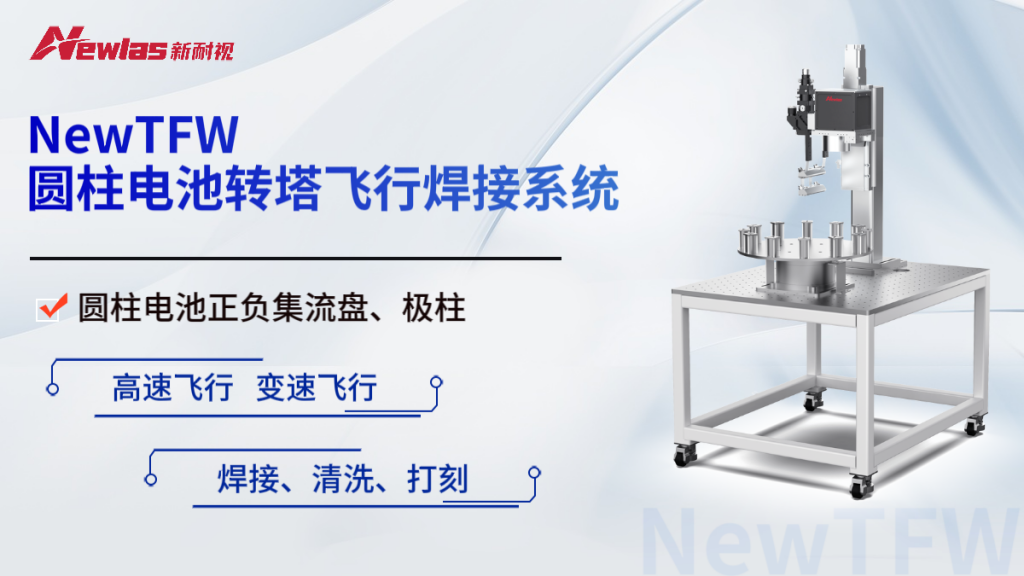

04 NewTFW cylindrical battery turret flying welding system

- Extreme performance: the maximum welding speed can reach 2000mm/s, and the turntable variable speed welding has zero downtime;

- All-round workstation: integrates welding, cleaning, and engraving, and improves both efficiency and accuracy.

Why choose Newlas? Four core advantages:

- Technology leadership: “Before welding, during welding, and after welding” is independently developed, and the NewOCT system has an industry-leading 10μm detection resolution.

- Full coverage of scenarioses: The four systems accurately match the three-electric manufacturing of new energy vehicles, deeply in line with the theme of CIBF. Solve the pain points of battery welding and adapt to the needs of complex production lines.

- Efficiency leap: Turret welding does not stop, flying welding has millisecond response, and the overall production efficiency is increased by 50%.

- Service empowerment: With the background of a national high-tech enterprise, it provides full-cycle services from solution design to implementation support.

From May 15 to 17, 2025, booth 9T118, Shenzhen International Convention and Exhibition Center, Newlas looks forward to joining you in the feast of new energy battery smart manufacturing